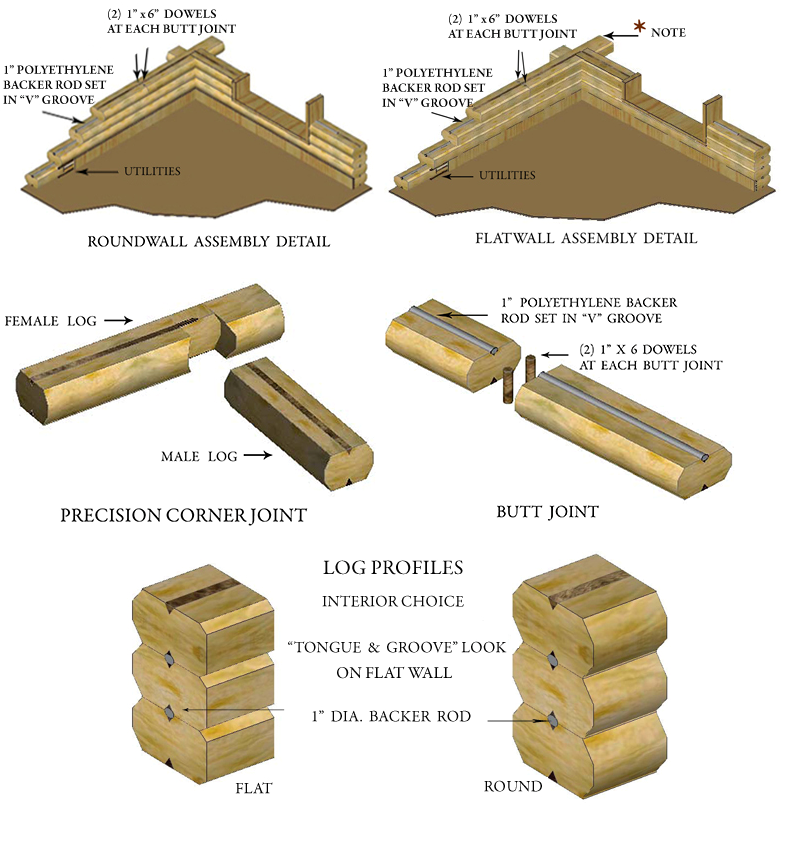

HOW YOU SAVE MONEY BETTER QUALITY - We provide the logs and the hardware required to put the log walls together. Log home companies providing additional items often ship a lower grade material than … Read More...

Lincoln Log Home Enterprises

Manufacturing log home kits to build a lincoln log home

Click here to receive a free brochure or inquire about replacement logs

Free Brochure

Call us about different sizes logs 1-800-848-3310 info@lincolnlogenterprises.com

Manufacturing

Manufacturing your Log Home

Lincoln Log Enterprises

6245 Meadow Lane

Salisbury, NC 28147

Office Number 1-800-848-3310

Building Homes … Building Dreams

Experience the joy of making your dreams come true! OVER 48 YEARS OF SERVICE